Compentek designs Fabric panels for equalizing thermal movements and vibrations in ductwork, boilers and process industries.

Equipment such as fans, filters, turbos and conveyors are often connected to the process using fabric bellows. A special advantage of fabric beams is their suitability for many applications, from gas turbines to air pipes. In addition to compression and stretching, the fabric beams receive rotational movement, which e.g. metal bellows are unable to receive. With the help of the raised frame solution, fabric beams can be used to connect parts of processes with more than a thousand degrees. The size of the bellows can vary from a collar-mounted small DN100 pipe up to 15x5m boiler bellows. The materials vary depending on the conditions, from single-layer EPDM-coated fabric to almost 10-layer gas turbine bellows.

With the right design, knowledge of the conditions and the right material choices, we can design and deliver not only a long-lasting

but also a very cost-effective fabric bellows solution to your process.

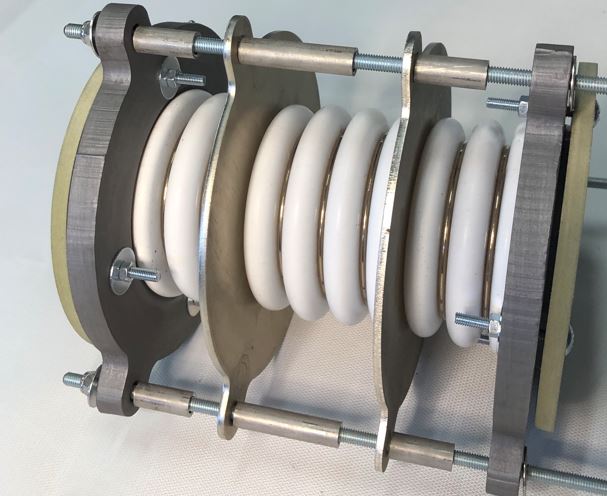

Fluachem 3N triple PTFE laminate bellows for aggressive gases.

- When choosing the bellows type and structure, e.g. the temperature and possible humidity of the gas or air passing through the duct. Gas-tight bellows types include e.g.

- Fluaflex© multi-layer construction, for hot exhaust gas and air ducts and process fans

- Fluachem© single/multi-layer structure for humid conditions and aggressive gases. Among other things, pipes, ducts, pipelines and fans. The materials are cross-laminated PTFE and elastomers such as Viton (FKM), EPDM, nitrile and butyl.

- Flexepdm© and Flexnit© single-layer elastomer bellows, e.g. for fans, also food approved

- Flexgns© for fans for wet gases. Layered and vulcanized EPDM rubber construction with integrated mounting flanges

- Fluastal© gas turbine bellows, up to 8 layers

- Flexpa© PVC fabric bellows straighteners, also food approved